Date: 07/24/2025

TABLE OF CONTENTS

Introduction

I have not made a blog post in a while, so I thought that I should chronicle a pretty cool time of my life.

This was my first year participating in the US Department of Energy's Collegiate Wind Competition (CWC). CWC is an annual competition where teams from colleges around the US compete to build a mini-scale wind turbine as well as design a wind farm, specific to the year's prompt. For 2025, we were tasked to build a floating wind turbine.

This was the first year MIT Wind qualified for the final phase of the competition, so our team was constantly scrambling to get things to work, but we still had a lot of fun in the process (well, I hope... at least I did).

Anyway, I would like to begin talking about my experience before I flew out.

(Would like to add that I am leaving a lot of stuff out on what electrical and project development accomplished since I am on the mechanical subteam. So sorry if I did not capture everything)

Cramming before flying out

A few days before the flight to Boulder, CO, where the competition was held, the build team was cramming in building N52.

The mechanical team was largely concerned with getting the foundation to float properly and the pitch control to move smoothly. We also needed to create a space for ports on the nacelle for the power and data cables.

Electrical also had a lot to do, as they were transferring all the electrical components onto PCB proto-boards, which required a lot of soldering. Also, soldering the load-side wires to the power plug was a pain, as the metal pegs were quite fragile and broke easily.

The day right before flying out, I was trying to help solder the wires onto the power plug, and we needed at least four legs out of the available seven (or six?). Anyway, we broke too many of them when trying to solder them, and we did not have an extra power plug. I recall running around campus trying to find the specific connector that we needed, as I felt rushed since the foundation at the time was not floating properly.

Thankfully, we ended up finding a spare power plug, and with better technique, the load-side wires were successfully attached. Around this time, my friend and I managed to get the foundation to float properly. Our issue was balancing how much weight and buoyancy to add. Adding more foam and steel discs managed to keep the foundation more stable at the time, but we eventually learned that this would not be stable in the presence of wind at the competition.

I pulled an all-nighter to build as much as possible before flying out.

The flight/travel

I was a husk of a human while traveling to Boulder. I broke my Wordle and Connections streak since my brain was unable to muster the energy to complete them. I also unfortunately lost my favorite water bottle after I passed though TSA.

After the flight, we took a rental minivan to our hotel and later got food. This moment is memorable to me because I ordered way too little food and stupidly mentioned how little food I received in front of the waitress; I still feel really bad about this. Afterwards we went to the local iconic hardware store called McGuckins to get some parts for the turbine. Little did we know that this would be one of many visits back to this beloved store.

The first day at the competition

Today, all we had to do was the tech inspection...

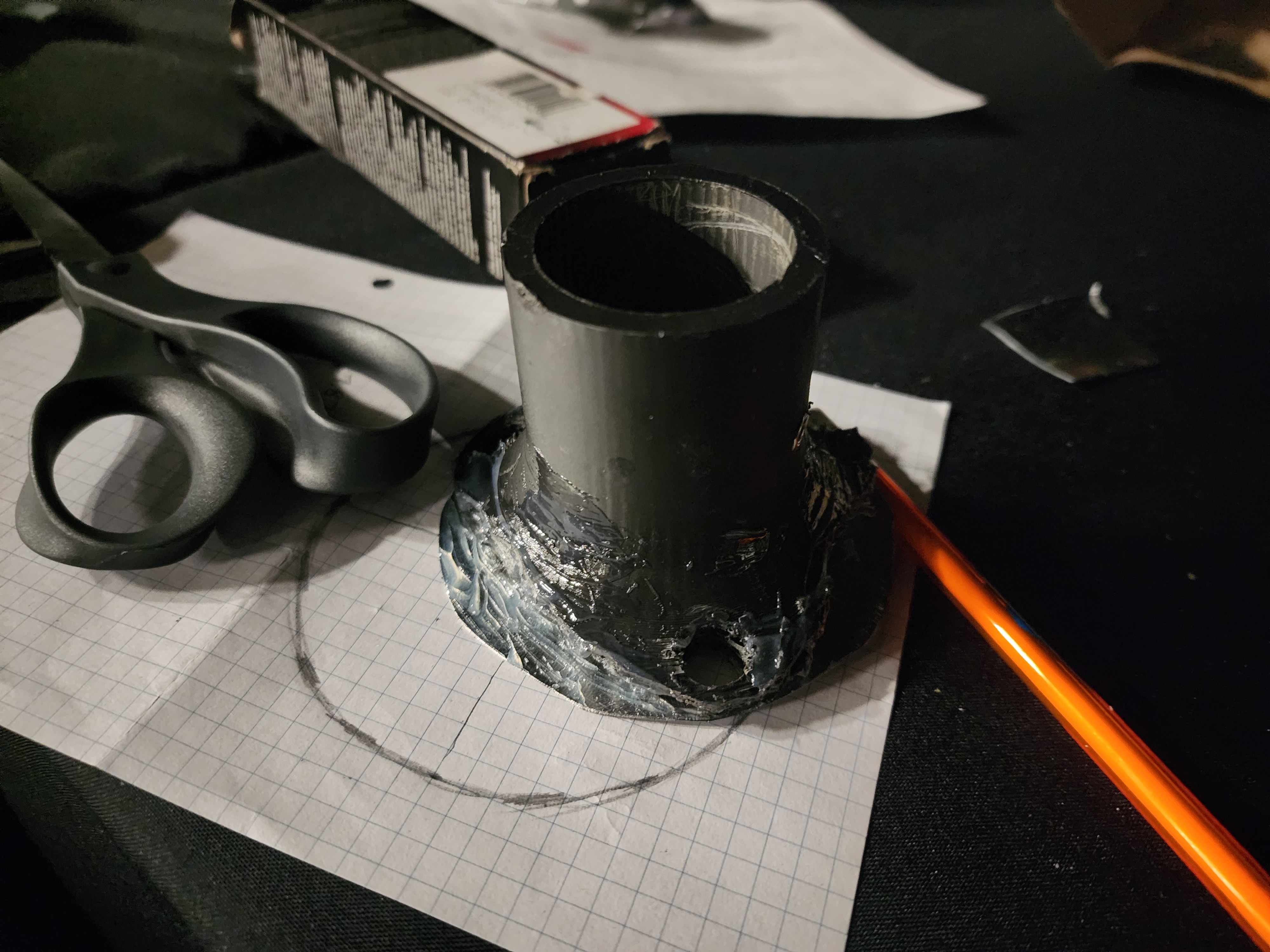

Ooh boy. We had many issues we never even thought about. The biggest challenge was fixing the base flange (for the steel pipe tower) so that it was within 9 cm in diameter and grounded.

Most teams accomplished this by making their base flange out of metal. Ours was merely 3D-printed—so made out of plastic and therefore ungrounded—and far too large in diameter. Electrical also had a lot to do.

Mechanical (which consisted of two people at the competition) scrambled for the rest of the day finding a way to fulfill the mechanical side of the requirements ASAP. Initially we tried running to McGuckins multiple times trying out different things. We bought a drill set, files, and a tin pan (only sheet metal we could find atm); the idea was to cut down the 3D-printed base flange into the desired size and drill out holes to make it fit onto the mounting studs. Then to ground it, we would cut out a tin circle and epoxy it to the bottom of the base flange. Unfortunately thin metal is hard to drill through cleanly, and I broke it :(((.

My team member was also working on a presentation that the build team was presenting the following morning. None of us had the time nor energy to spend much time on it, but my friend (pulled through for us fr!!!) managed to throw together slides with stuff from the poster/report.

The second day

At 8:45 AM, we were running up and down mountainous Colorado terrain to make it to our allotted presentation time, and we were direly unprepared. We started promptly without any rehearsal, so I was just up there unsure when it was my turn to step in and say stuff. Eventually I felt that it was my time, and it was... a time. I did not know what content the slides were going to show, so it was somewhat of a mess on my end.

After we finished presenting, the judges tried reassuring us by saying how brave we were to be there, as they claimed that many other teams seemed unconfident or apprehensive. In reality we were all too exhausted to put much thought into our performance. I was, for sure.

We found it funny how the judges said that they liked our prioritization of visuals for the slides—our slides had no labels or text, mind you—as other teams tended to include big blocks of text. However, this was because we simply did not have the time to add more text and labels to the slides where they were somewhat necessary.

Anyway, now that the presentation was finally over, we had to return to the reality that we were at risk of never passing tech inspection, which would lead to our disqualification from the graded competition.

However, the tides shifted, and the sun aligned with the moon; by some miracle, a team let us borrow their 3D-printer to print out a new base flange! We were saved...

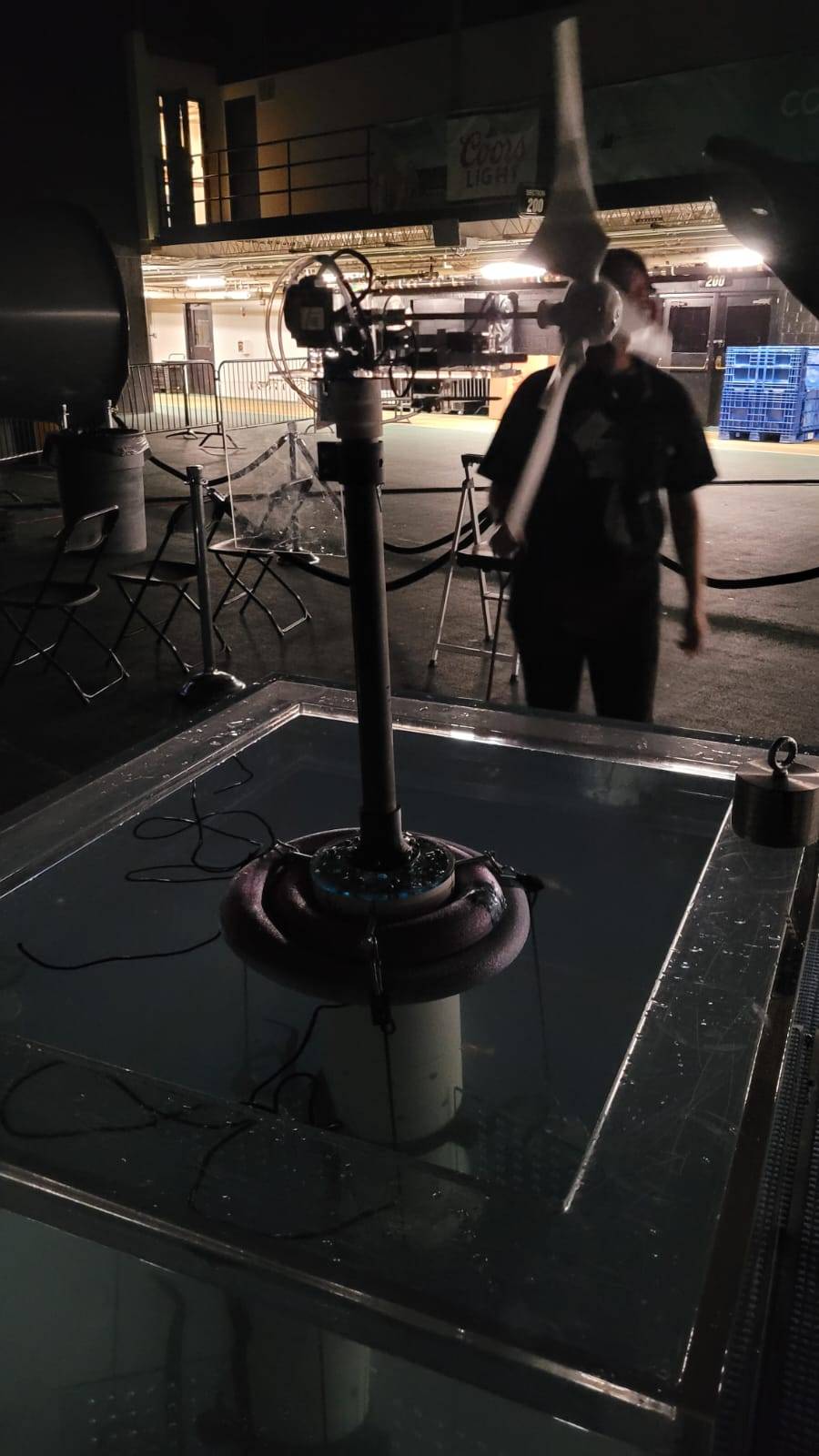

...until we went to test for the first time. Our foundation did not float, so we had to turn our first test session (out of two) into a practice run. From this session, we learned that we needed to increase the buoyancy and make the center of buoyancy higher so that the foundation was more stable, all while making the foundation shorter as it was too long. Additionally, we needed to prevent the foundation from tipping too much because it couldn't tip past 15° according to the rules.

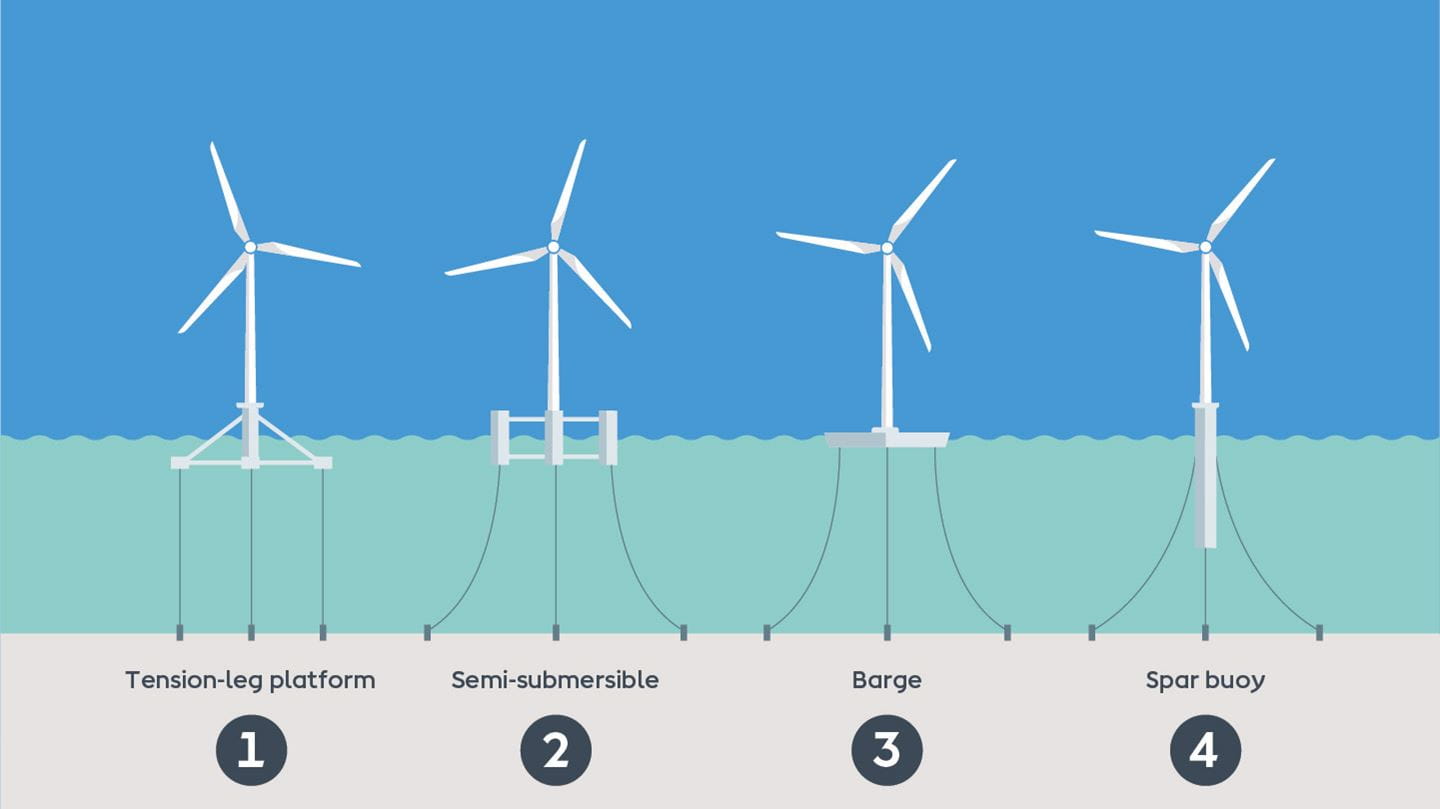

To address all concerns, we (1) hacksawed off a centimeter from the bottom of the steel tower to really squeeze in as low a center of mass as possible, (2) hacksawed off as much as possible from the bottom of the foundation to make it less likely to touch the bottom of the tank (thank you so much Cal Maritime for lending us your hacksaw), (3) bought some pool noodles to wrap around the top of the foundation, and (4) extended the bolts used to secure the foundation topper (we called it the "puck") to keep the pool noodle rings secure and to add another set of mooring lines. Interestingly, this made our foundation somewhat of a combination of several types of floating wind turbine foundations: tension-leg platform, spar buoy, and barge.

The third day

We finally had the foundation ready for our final test, and we ended up passing all foundation related scoring! However, our turbine did not generate any power. We believed there may have been an open circuit since we did not feel any resistance from turning the generator, but electrical tested that it was not, so we're just unsure.

We asked the mentor from Cal Maritime about his thoughts on our design, and he said that we should simplify the circuit as much as possible. For instance, he did not really like how we were using a MOSFET as an adjustable resistor since it did not seem to be very reliable. Cal Maritime used a different method for adjusting the load (I think they just used a bunch of different resistors), so maybe we can take inspiration from their design.

We received a lot of help from Rice students as well! They told us that the key to generating more power wasn't actually too dependent on the pitch of the blades but instead the load; we should look more into this. They also reassured us that we did pretty good for our first competition since we were a small team compared to all the other ones there.

Final thoughts

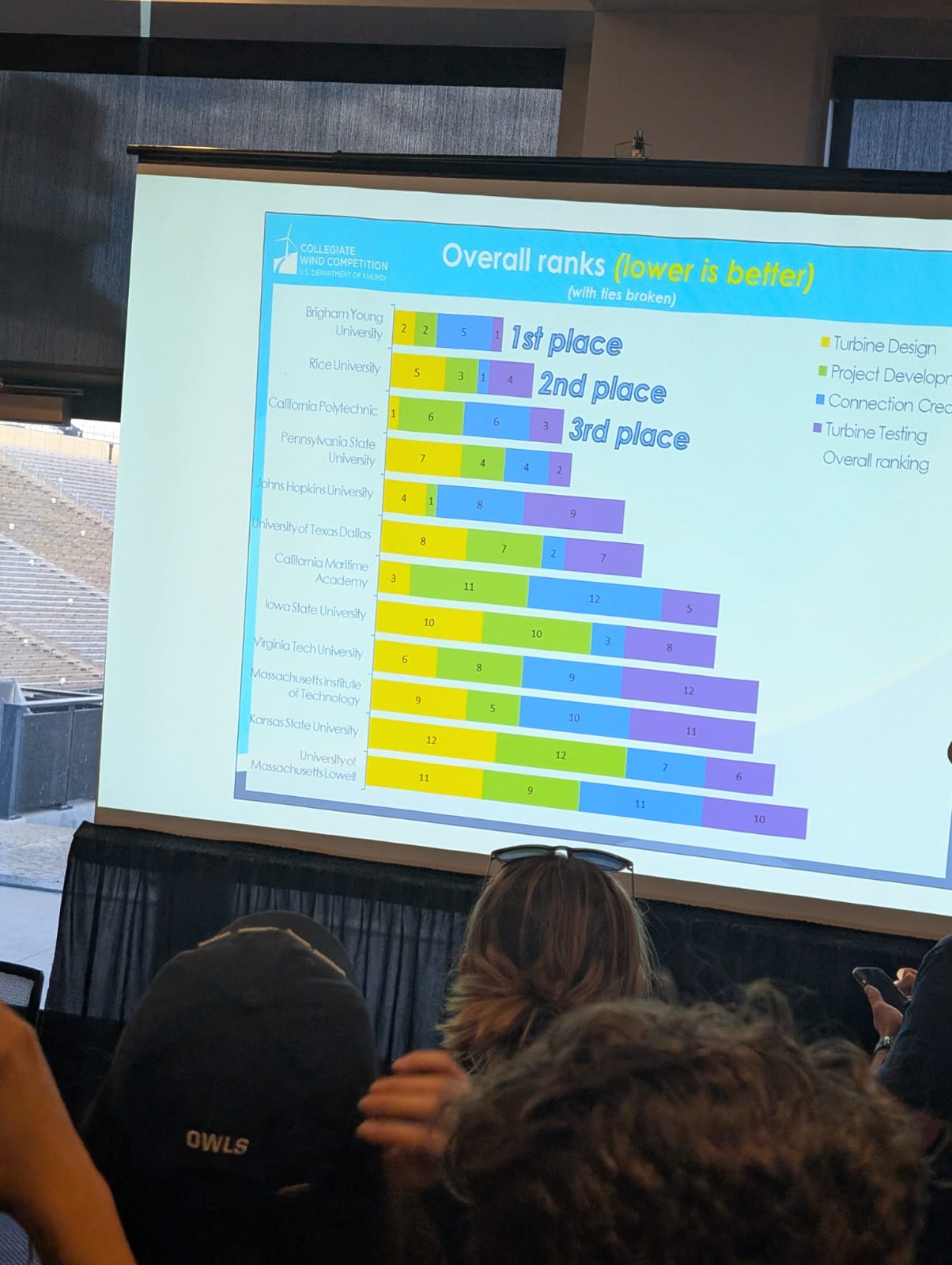

Well, we placed 10th out of 12 teams, but I am still beyond happy with this outcome. I was just surprised we were not disqualified since there so many hurdles to getting the mechanical side of the foundation through tech inspections. I liked how the judges acknowledged how hard we worked over the few days, as they called us up to give us a mechanical fish (this was the only "trophy" we got besides the participation award haha).

This competition taught me a lot about better engineering. For instance, I should have been more mindful of the constraints of the competition and realized how difficult it would be to keep the spar buoy from tipping. I think due to the limited depth allowed in the tank, a spar buoy foundation may not have actually been the best design while keeping the foundation reasonably heavy, but this would have been hard to tell at the time, and the additional mooring lines were sufficient in keeping the foundation from tipping too much.

One thing I would like to do is build a custom generator for MIT Wind, as most teams at the competition built one, and it seemed to be a major plus for the design report (not to mention it being cool af). First, I want to try building a classic radial flux three-phase generator, but eventually I would like to make an axial flux generator since they're known for being more compact and efficient than radial flux ones. The main drawback, however, is the complexity and precision necessary to manufacture one. It seems like a fun challenge.

I also just want to squish in that this competition felt very nostalgic, as it harkened back to the chaotic days of high school robotics for me. I did VEX Robotics and lived and breathed it for the majority of my high school career, so I liked being able to fully immerse myself in something buildy again.

Fun pics

See more

- Next: Attempting to build a generator - part 1

- Previous: Why Hummingbirds Are Amazing