Timeline: March-May 2020

Objective

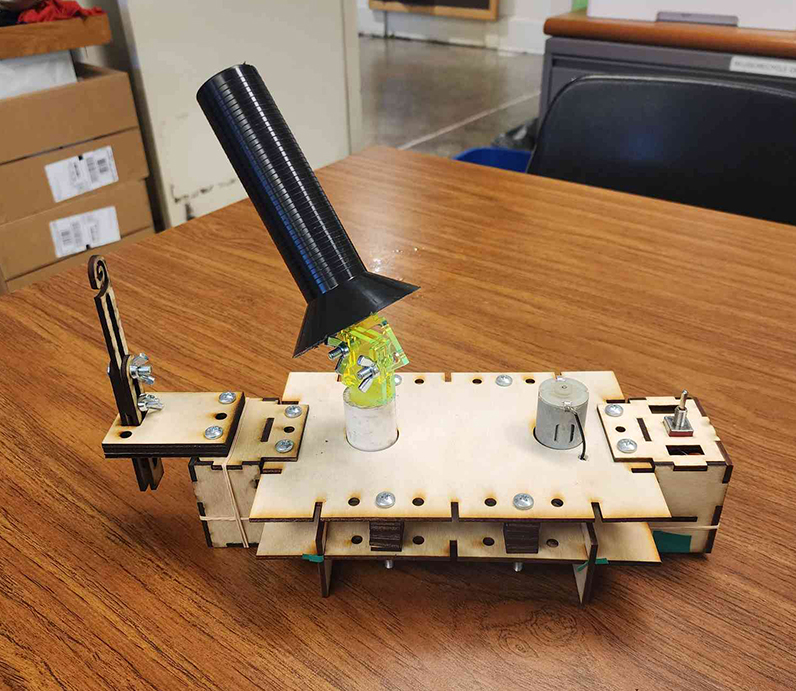

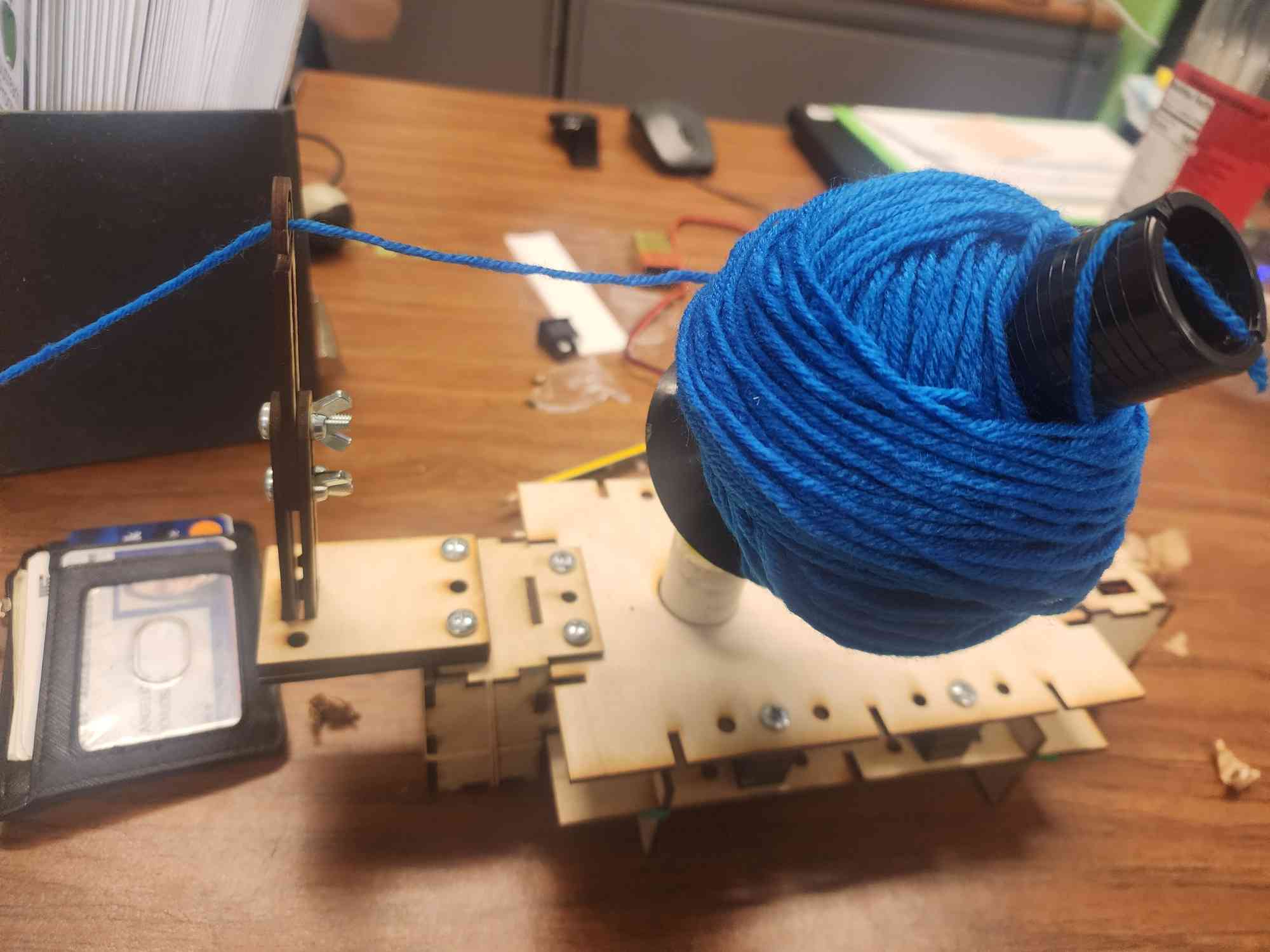

Prototype entirely made out of scavenged parts (total budget: $0). The many crochet and knit projects that I abandoned motivated me to build this, as I wanted to speed up the process of frogging (frog meaning "rip it, rip it") them.

Outcomes & Contributions

I used scrap 1/8th inch acrylic and plywood from the Edgerton Center Student Project Lab to laser cut the gears and base (designed using Fusion 360), and I scavenged for all the other parts, including an empty spool from my work for the bent winding part and a brushed DC motor found in the EE lab of my dorm's basement. A 9V battery powers the winder, and I soldered the entire circuit (except for wires attached to motor so that I can take base apart), which includes a double pole switch for bidirectional movement of the motor. I also designed the yarn feeder and angle of the winder to be entirely customizable, with just a few bolts and wingnuts, for adjustability and possibility for different winder attachments, which is something that I noticed lacking in most commercial yarn winders.

Technical Details & Skills

CAD: Autodesk Fusion 360

Manufacturing: Laser cutting, bandsawing, soldering